- contact.miraclefresh@gmail.com

- +84 906 921 688

- Download Brochure

Loss after the harvest

Post-harvest losses are estimated between 10 and 30% of agricultural output. This is a huge loss in agriculture.

In addition to the loss of production, there is a significant decrease in the quality of agricultural products such as loss of nutritional content, changes in taste, shape, being contaminated by fungi and bacteria...

The causes of losses can be mentioned as mechanical losses during harvesting and transportation, losses from insects, rats... damage, losses due to microbial contamination (bacteria, mold, yeast...), losses due to physiological changes such as ripening or wilting too quickly...

Microorganism

Microorganisms including molds, yeasts and bacteria cause sensory changes in agricultural products and vegetables such as rot, fermentation, odors... and worse, create. The metabolites are harmful, poisonous to those who eat them.

In addition, the microorganisms themselves can enter the human body when exposed to infected agricultural products, causing many illnesses that seriously affect consumers' health.

The rate of damage caused by microorganisms in agricultural products is very large, especially in hot and humid climates like Vietnam. Antimicrobial resistance is one of the top priorities of storage.

"Ethylene Gas"

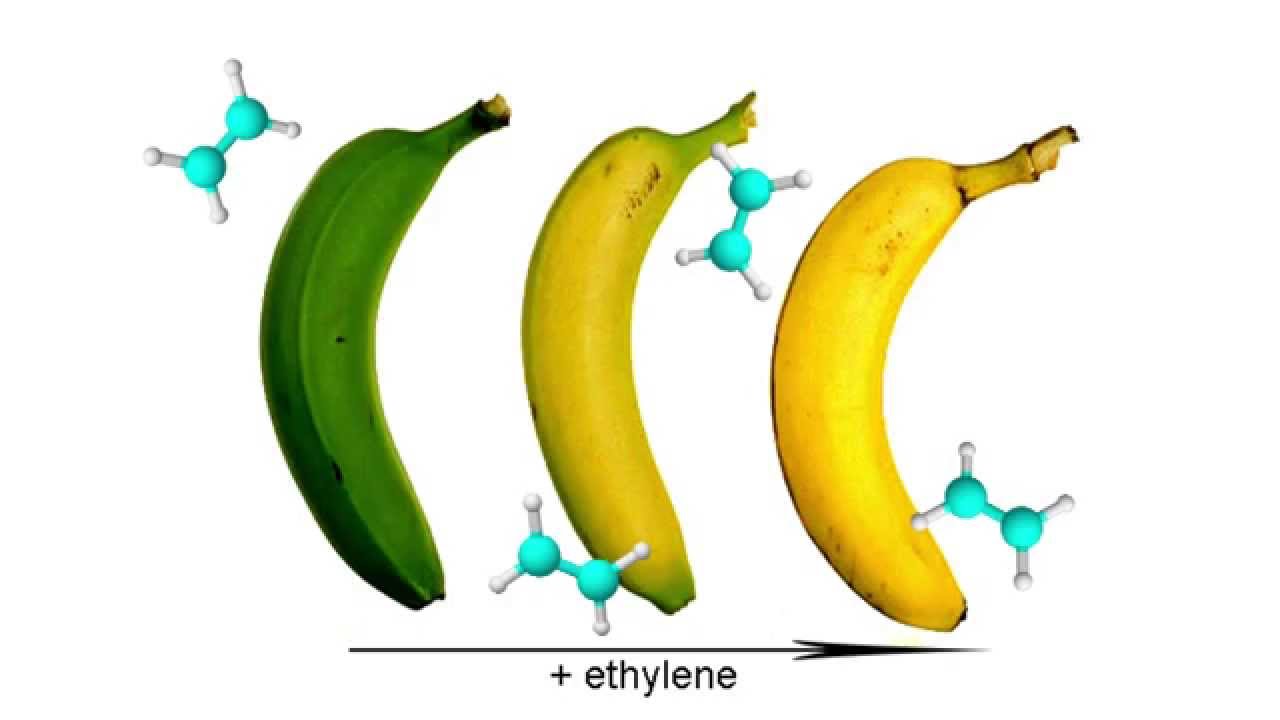

Ethylene is a plant hormone (phytohoocmon) formed during the plant's developmental stage, is a natural product of plant metabolism and is formed in small amounts in all different tissues of the plant.

Ethylene causes physiological effects in plants such as promoting the ripening process of many fruits, yellowing of vegetables... Many fruits and vegetables continue to produce ethylene gas after harvest.

Therefore, after harvesting agricultural products, controlling Ethylene concentration is extremely important. Agricultural products will rot in a short time if Ethylene concentration is too high.

MIRACLE FRESH

Vegetables in the near-ripening period (usually the post-harvest period) produce large amounts of ethylene (endogenous ethylene) to speed up ripening.

MIRACLE FRESH causes conversion of ethylene gas (C2H4) into carbon dioxide (CO2) and water (H2O). The reduction of ethylene gas, together with the increase of carbon dioxide and moisture creates an ideal environment to slow down physiological changes, maintain the freshness of vegetables and fruits...

In addition, with the anti-Bacterial and Mold resistant mechanism, it helps to avoid damaging agents from the preservation environment.

Benefits of MIRACLE FRESH

Significant reduction in labor productivity and handling costs of damaged products.

The product is preserved for a long time, the quality and quantity of agricultural products do not decline much in the long term, so it will avoid being forced to sell at a cheap price.

MIRACLE FRESH preserving packaging is very convenient, suitable for many types of agricultural packaging, simple packaging manipulation.

Long storage time, suitable for low-cost long-term transport services.

Can export far to high-end markets such as the US, Europe, Japan... Bringing great profits.

Using MIRACLE FRESH technology of Japan is a certification and quality assurance of agricultural products when exported to international markets.

(Broccoli can stay fresh for 25 to 30 days)

MIRACLE FRESH testing in Japan

The test sample in the MIRACLE FRESH bag, at a temperature of 5°C. Follow up continuously for 21 days.

※The test was conducted in Japan.

※The storage conditions are for reference only.

※Results may also vary depending on the surrounding storage environment, crop, variety, region of origin...

Read More...

Appearance: No change after 21 days.

Internal: Still fresh, juicy.

Appearance: Retains its freshness and shine after 21 days.

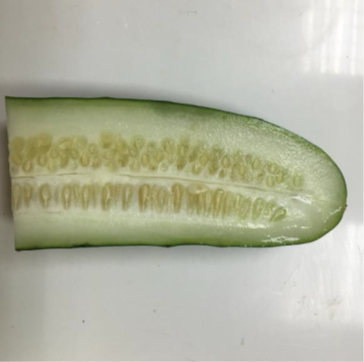

Internal: Some bruises appear when peeled - When cut in half, the flesh inside remains fresh.

Appearance: Slightly softened after 21 days.

Internal: The mesocarp is not too ripe.

Appearance: The exocarp has slightly darkened after 21 days.

Internal: Still fresh, the color does not change, still retains the crunchiness.

Appearance: No change showing signs of change after 21 days.

Internal: The mesocarp is slightly mushy.

Appearance: The exocarp is slightly yellow, with few small bruises.

Internal: The mesocarp is not too ripe.

Appearance: Still fresh after 21 days.

Internal: Fruit not wrinkled, dry.

Appearance: Retain freshness after 21 days.

Internal: The pericarp is still fresh and the seeds don't sprout.

Appearance: The exocarp begins to turn slightly dark after 18 days.

Bên trong: The pericarp retains its firm texture and freshness.

Appearance: The exocarp has been discolored.

Internal: Nothing unusual happened. The mesocarp is still fresh and elastic as originally.

Appearance: There are no abnormal changes in appearance.

Internal: The mesocarp is still fresh and crispy.

Appearance: The outer leaf has withered.

Internal: The inside is still fresh.

Yellowing began after 18 days. Begin to rot after 21 days.

Yellowing began after 18 days. Begin to rot after 21 days.

Appearance: The leaves begin to wilt on the 14th day and after 18 days are not eligible for sale.

Internal: The inside was watery and could not be eaten.

MIRACLE FRESH testing in Vietnam

The test sample in the MIRACLE FRESH bag, at a temperature of 5°C.

※The test was conducted in Vietnam.

※The storage conditions are for reference only.

※Results may also vary depending on the surrounding storage environment, crop, variety, region of origin...

Read More...Grapes after 21 days

Almost all grapes have withered. Inedible.

Fungal infection since day 7. There are a few grapes rotten, fall stalk.

Only a few grapes rotten, stalked. The rest is still fresh.

Broccolies after 21 ngày

Began to yellow and wither on day 7. Ineligible to eat.

Change to light yellow on day 7. After 14 days of completely yellow color.

Still fresh after 18 days. Slight yellowish on the 21st.

Figs in 12 days

The Fig ripe faster when not using MIRACLE FRESH.

Freshness is maintained after 12 days.

Preserving Broccoli 25 days in China

Cover the MIRACLE FRESH preservation film inside the foam container. Put Broccoli and Fresh Fruit inside. Cover and seal (with a few small holes in the lid of the container) and keep at 4 - 5°C for the duration of storage.

※The test was conducted in China.

※The storage conditions are for reference only.

※Results may also vary depending on the surrounding storage environment, crop, variety, region of origin...

Read More...Results of preserving broccoli after 25 days - The temperature in storage is kept at 4 - 5°C.

Results of preserving broccoli after 25 days - The temperature in storage is kept at 4 - 5°C.

Results of preserving broccoli after 25 days - The temperature in storage is kept at 4 - 5°C.

Coat the MIRACLE FRESH film on the fruit bin. Store in refrigerated container at a temperature of 5°C

English

English

Tiếng Việt

Tiếng Việt